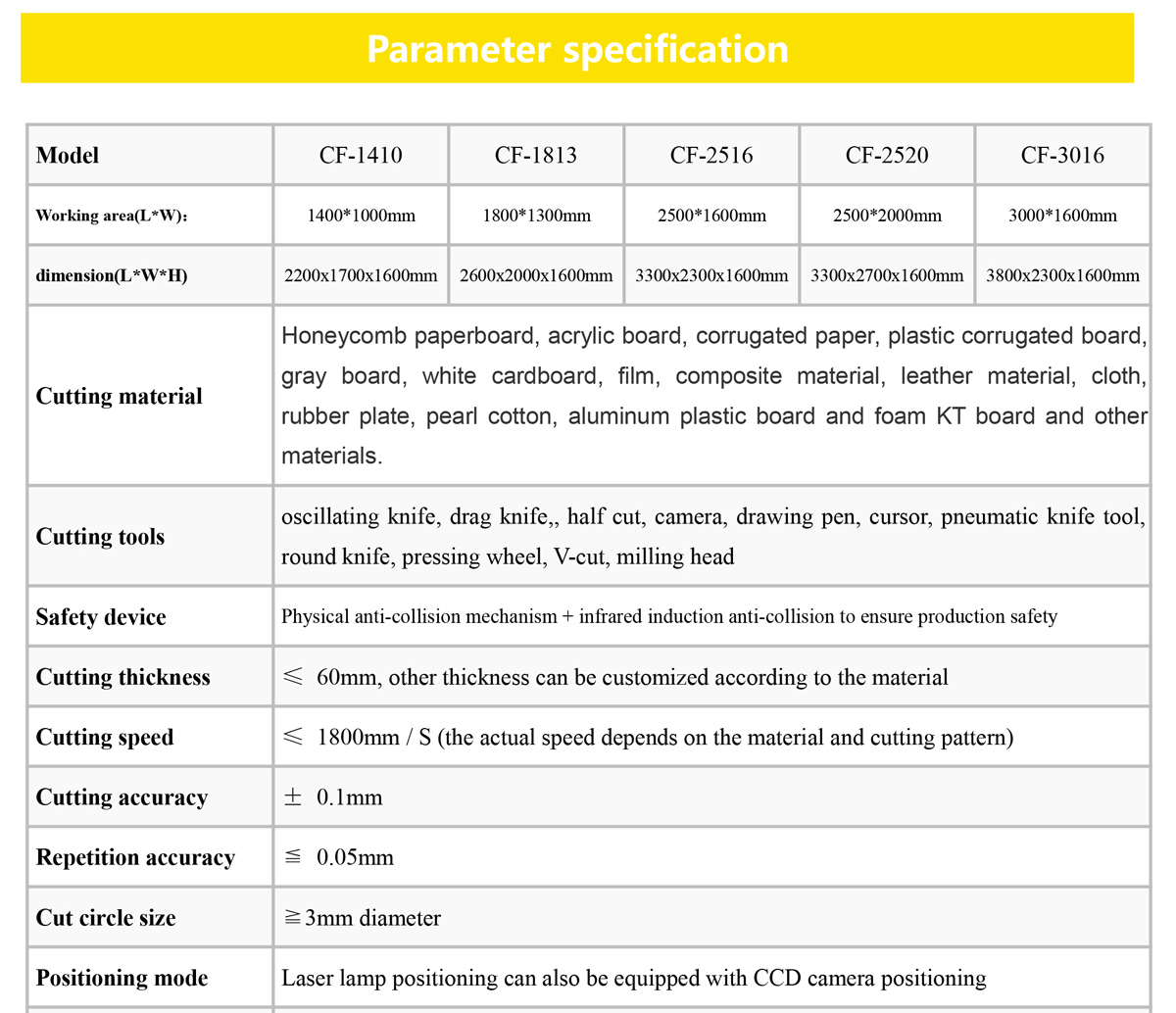

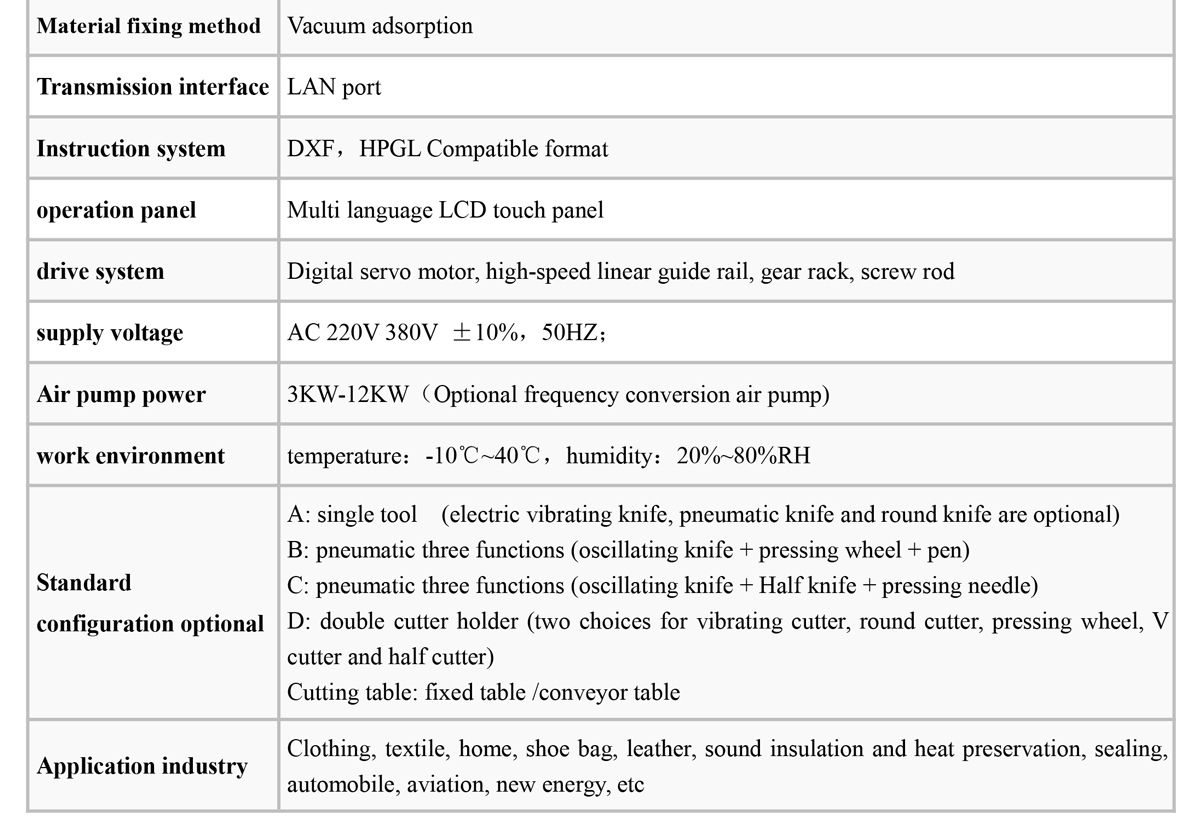

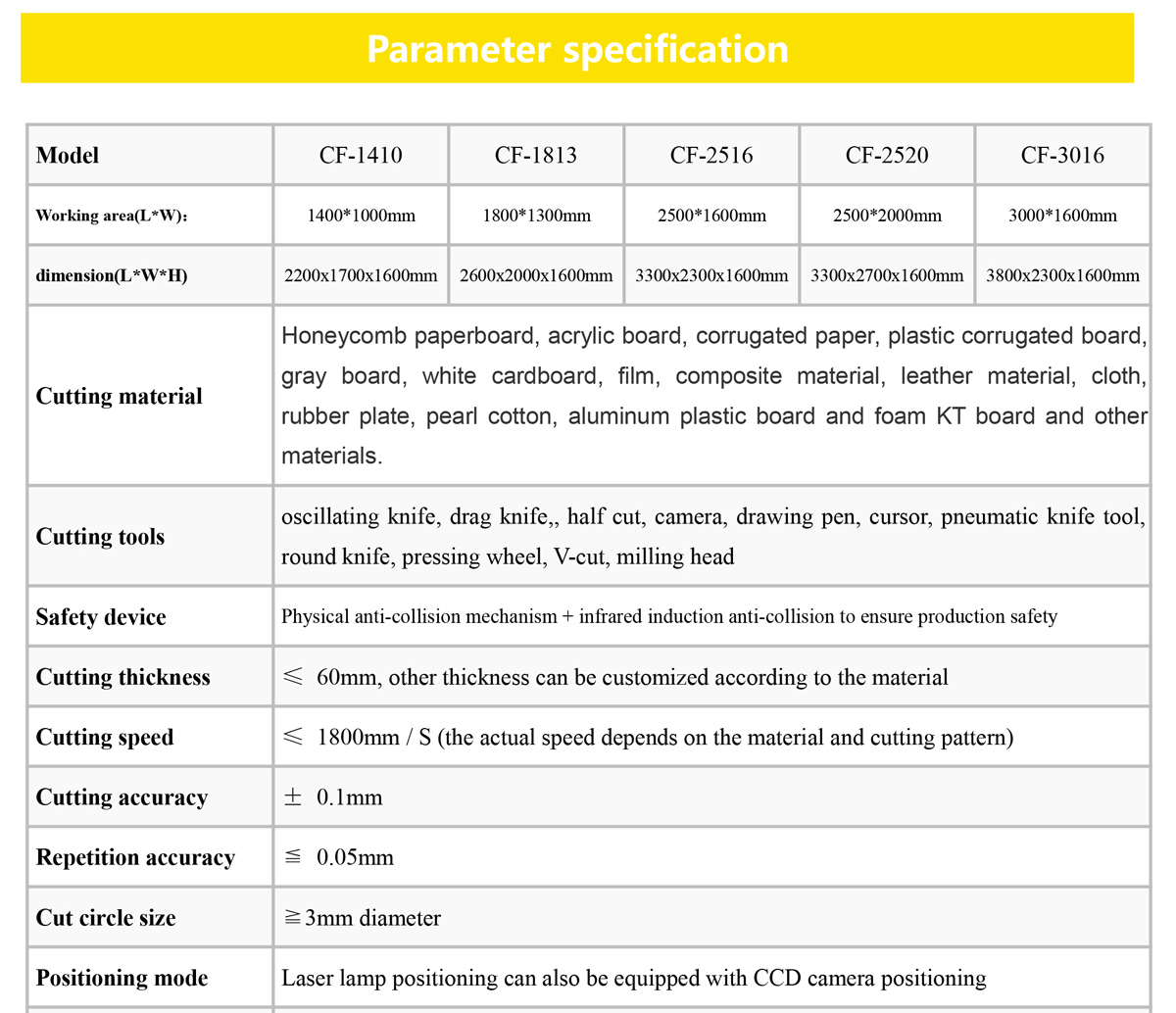

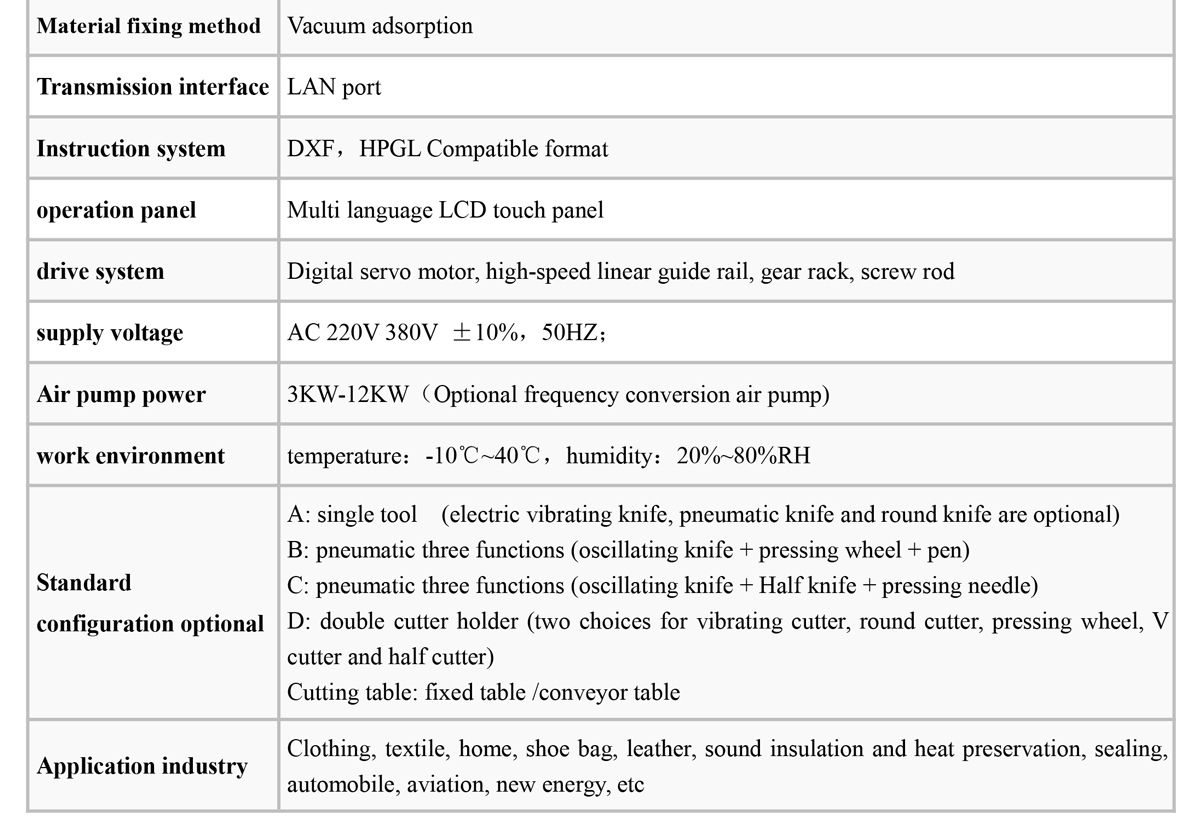

The picture is for reference only, subject to the actual machine! Support non-standard customization

The gasket cutter is mainly used for automatic intelligent cutting of flexible sealing materials, including asbestos gasket, sealing gasket, asbestos free plate, asbestos rubber plate, graphite composite plate, rubber, PTFE, etc. It can complete the special-shaped processing of sealing parts with high precision and more stability, and the finished work piece is flat and smooth without sawtooth and burr. No tool die, save materials and rapid production. Effectively solve the problems of aging employees in the sealing industry, low production efficiency, dependence on manual experience, low material utilization rate, difficulty in manufacturing special-shaped parts and non-standard specifications, chaotic document management, high product scrap rate and long delivery cycle, and help customers in the sealing industry reduce costs and improve efficiency with high quality, short production cycle Customized customer service to win more market share!

Compared with traditional die punching and CO2 laser cutting, the cutting machine in the sealing industry does not need a die, which saves time and effort. It has the characteristics of accurate sample cutting, smooth edge, no sawtooth, no yellowing and coking, no powder, dust, peculiar smell, safety and environmental protection, convenient maintenance and low cost. Users can also choose large vision system, projector, multi head, multi beam Lengthen and widen the working area of the cutting bed to meet different personalized production needs.