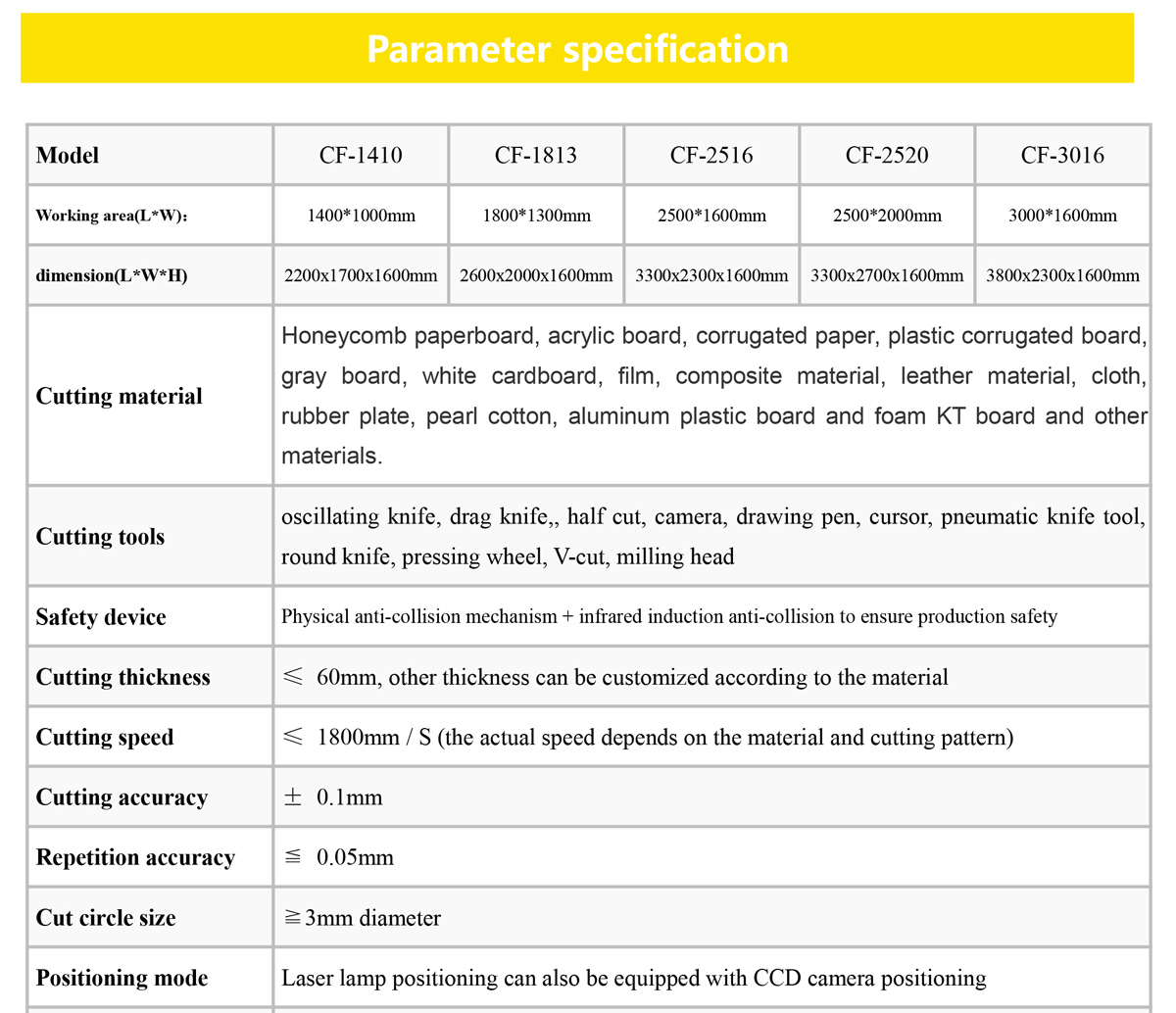

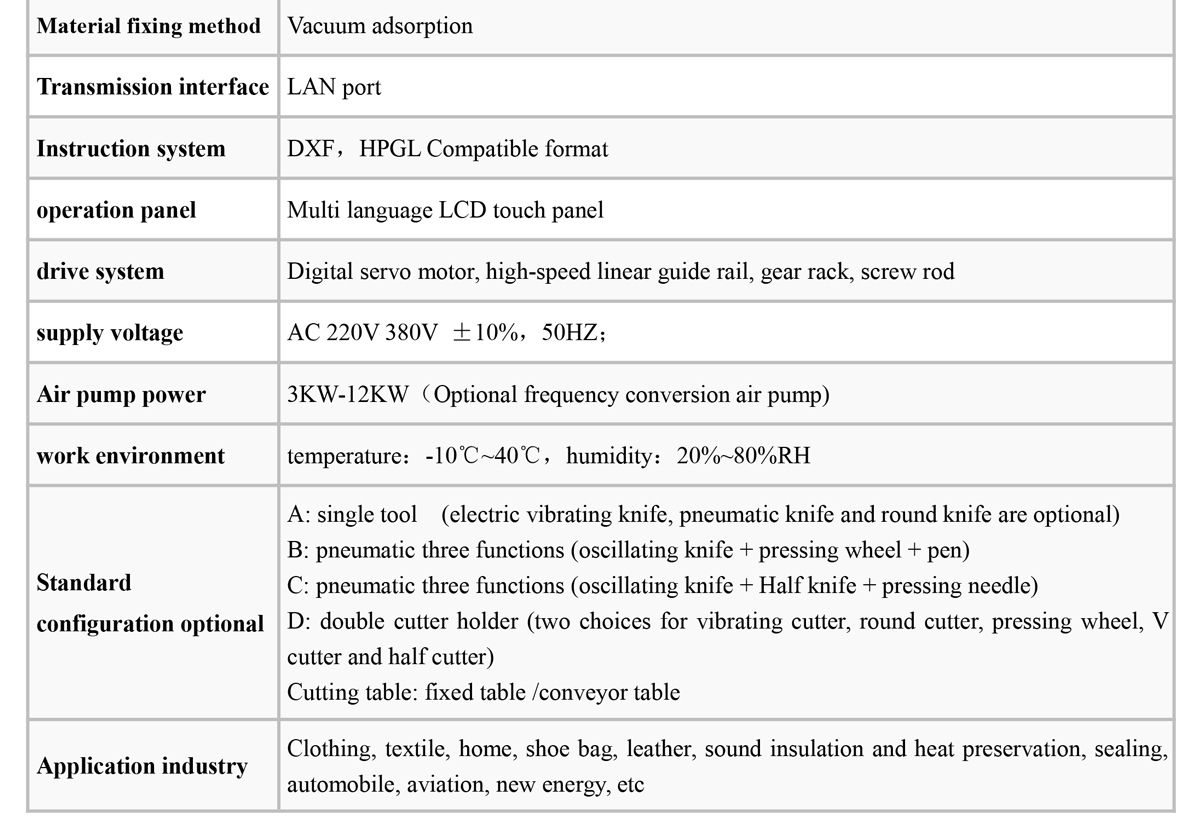

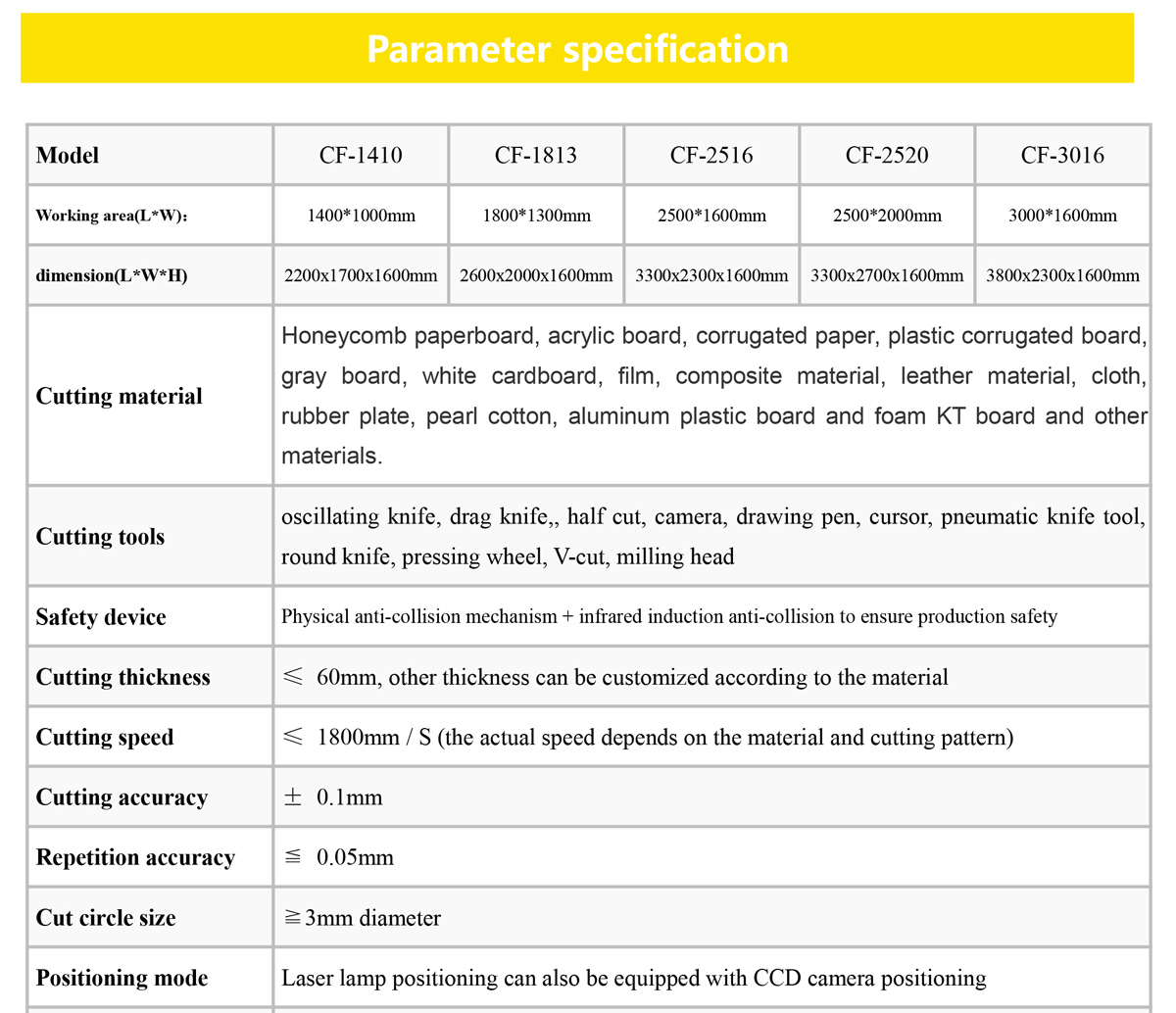

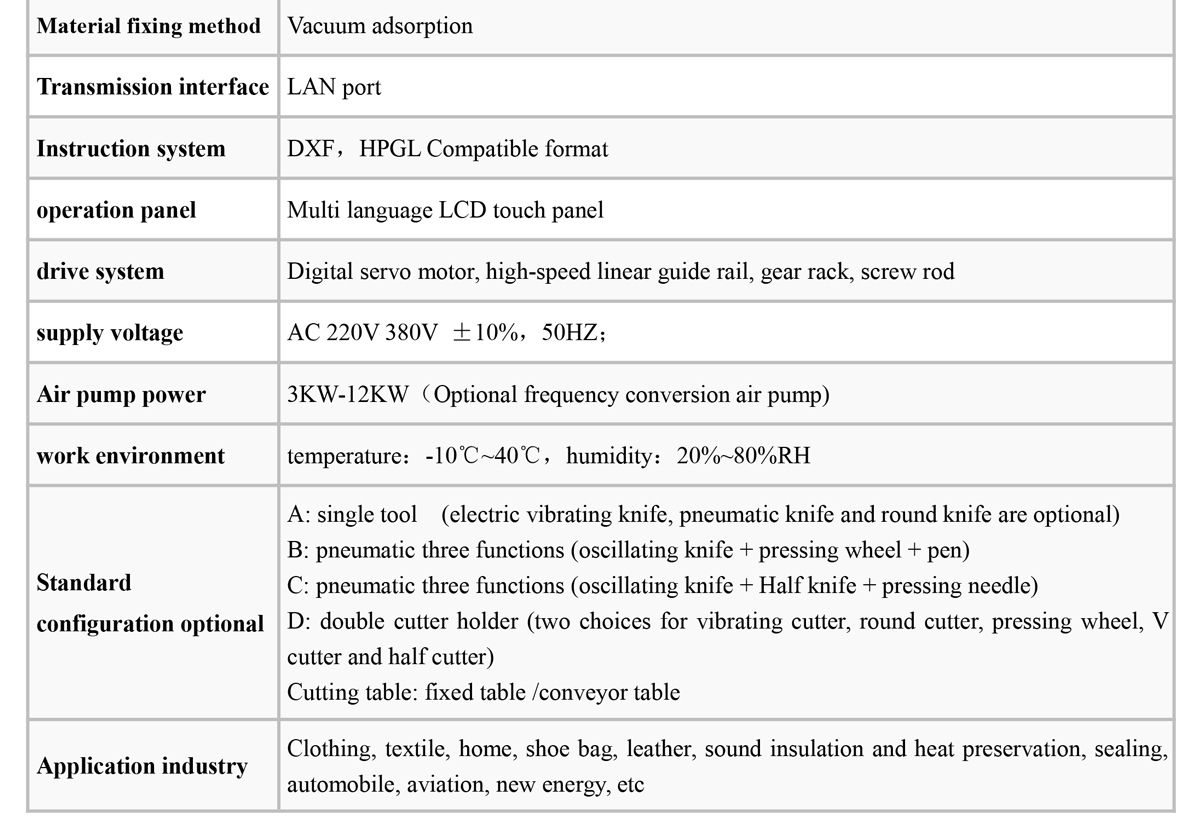

The picture is for reference only, subject to the actual machine! Support non-standard customization

Garment textile cutting solution

Chengfei cutting system provides professional solutions for proofing and small batch production in textile and garment industry. Equipped with high-speed driving wheel knife, electric vibration knife, pneumatic vibration knife and the third generation punching machine head (PPT machine head). Whether you need to cut chiffon, silk, wool and jeans, you can provide suitable cutting tools and schemes for different types of cutting rooms such as men's clothing, women's clothing, children's clothing, fur, women's underwear and sportswear.

Printed garment cutting machine - Garment proofing, suitable for high setting garment cutting, and supports automatic grid and strip matching.

Edge finding and cutting machine for printed clothing - suitable for industrial suits, printed swimsuits, plaid shirts, etc.

Fur cutting machine - suitable for fur, granular velvet, fur, leather and other materials in the industry.

Textile cutter materials - cuttable balloon silk, felt, functional textiles, molding materials, fabric banners, PVC banners, mats, synthetic fibers, raincoat fabrics, carpets, carbon fibers, glass fibers, aramid fibers, prepreg materials, roller blinds, beach flags, sunshades, sand releases, curtains, pillows, bedspreads, carpets and floor coverings

The intelligent cutting machine can finish the special-shaped machining of workpieces with high precision and more stability, save materials and produce quickly. Compared with traditional CO2 laser cutting, it has the characteristics of accurate sample cutting, smooth edge, no sawtooth, no yellowing and coking, no powder, dust, peculiar smell, safety and environmental protection, convenient maintenance and low cost. Users can also choose large vision system, projector, multi head, multi beam, lengthening and widening the working area of cutting bed to meet different personalized production needs.

Typesetting and material saving: the extreme automatic tight typesetting function minimizes material waste and improves fabric utilization.

Cutting tools: equipped with active round knife tools, single-layer cutting cloth, imitation leather or other textile materials do not need coating, and vibrating knife tools can also be equipped to realize multi-layer cutting.

Cutting tools: a variety of cutting tools can be configured to cut the fabric efficiently, including v-mouth and round mouth, so as to solve the problem of cutting the fabric of sofa and clothing.

Feeding and receiving device: various feeding racks (including deviation correction rack) and receiving platform can be configured to meet different needs.

Grid to grid: if there are requirements for grid to grid, the intelligent grid to grid system can be configured to complete the cutting of grid fabric.